Compressive strength is measured in pounds per square inch (psi). What psi is needed for under slab insulation? Read on to find out.

Continuous Insulation for Basement Walls 101: Achieving the Best Results with the Best Insulation

The Best Cold Storage Insulation Option

Understanding the R-Value Per Inch of Mineral Wool Insulation

A Look at Rockwool Comfortboard and a Fantastic Alternative

Rockwool Comfortboard 80 is a modular rigid stone wool insulation board made from rocks. If you’re going for a big-bad-wolf-proof building, Rockwool should be on your list to consider for insulating your exterior walls. Rockwool isn’t perfect for every application though, it can be expensive, heavy, and challenging to install.

Here, we cover the major benefits of Rockwool, its shortcomings, and what other options are available to insulate your walls in your home or commercial project.

Benefits of Rockwool Board

Rockwool has a number of things going for it. Here are some of the benefits of choosing Rockwool Comfortboard 80 to insulate your project:

Made from natural and recycled raw materials

Excellent fire resistance with no smoke production or flame spread

Termite and insect resistant

High compressive strength

Provides acoustic sound absorption

Where to Use Rockwool Comfortboard 80

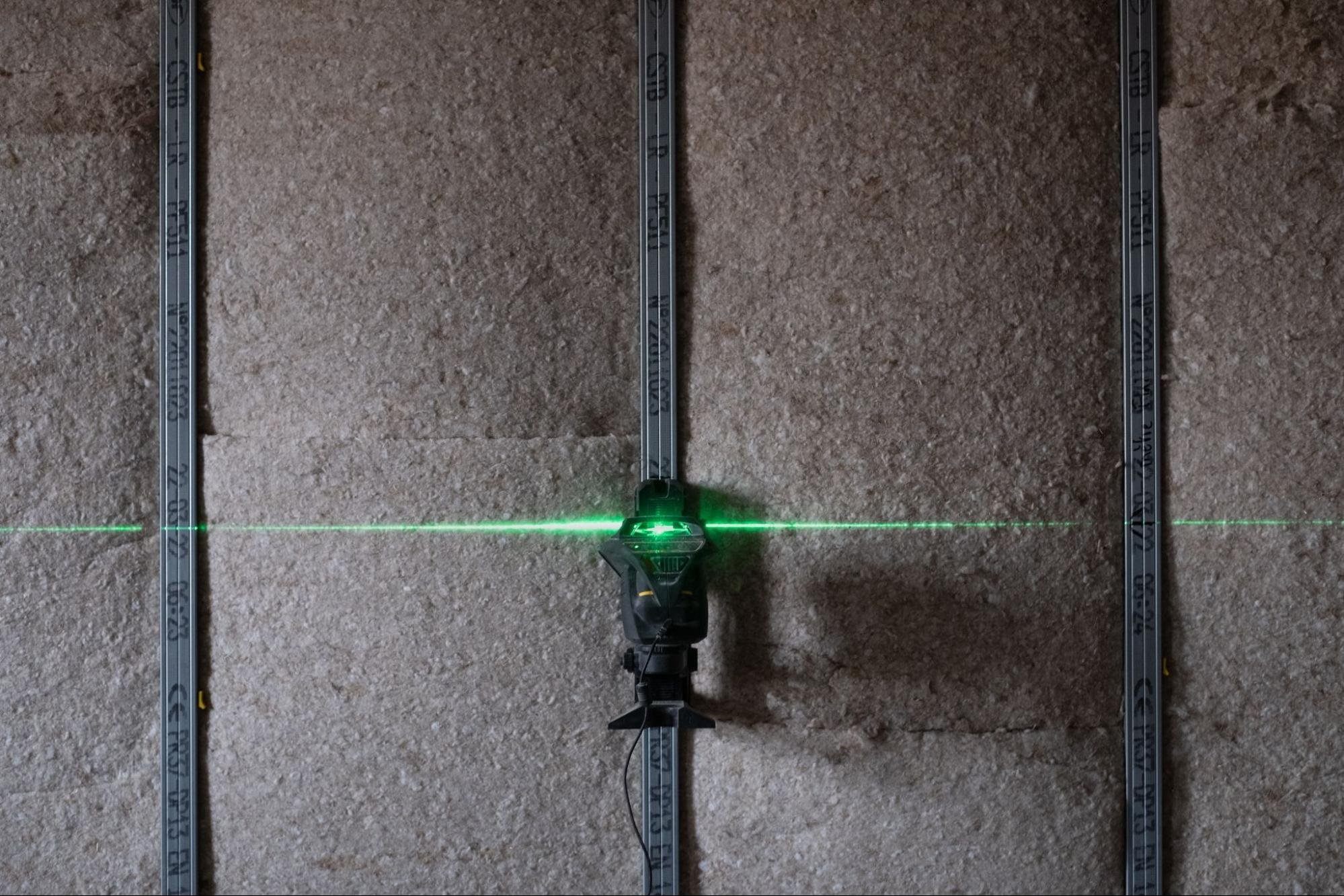

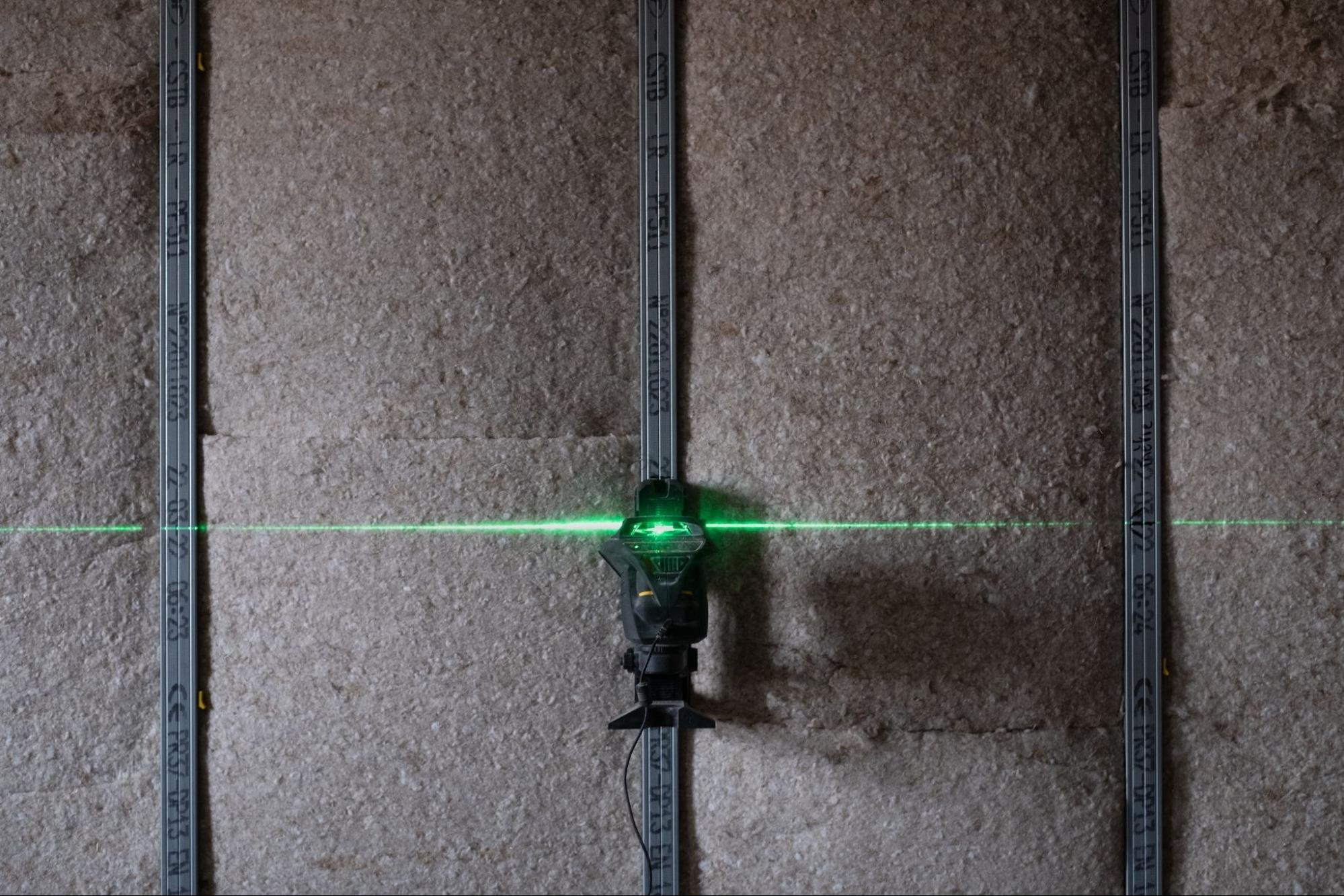

Rockwool Comfortboard 80 is designed for use on the exterior side of the wall for continuous insulation. It’s installed with 3-inch washers and nails, and is attached to sheathing over a vapor barrier or house wrap. Other applications can include foundation walls and under concrete slabs.

Disadvantages of Rockwool Insulation

Rockwool is a great option for some projects, however this type of insulation isn’t always the best for every application. Some of the shortcomings of Rockwool Comfortboard include:

Weight

It’s heavy, at over 50 lbs. per 4’ x 8’ board at 2” thickness, which makes installation laborious.

R-Value

At R4.2 per inch, Rockwool Comfortboard 80 is a middle-of-the-road option when it comes to thermal R-value performance.

Cost and Availability

Rockwool Comfortboard 80 can be difficult for homeowners to obtain because it is not typically stocked in big box stores, so it can be a challenge to obtain, and pricier to purchase.

An Alternative to Rockwool

Luckily, there is an alternative to Rockwool Comfortboard 80. Polyiso is a comparable option to Rockwool when it comes to installing insulation on walls. Taking it a step further, polyiso outperforms Rockwool when it comes to installability, thermal performance, and price point. If you’re looking for a less expensive, lightweight alternative to Rockwool—without sacrificing on performance, consider polyiso.

Easier Installation

Polyiso can be installed in the same locations and applications as Rockwool as a continuous insulation, but with significantly less weight bearing on your installers and your walls. Since polyiso is made out of foam, it’s inherently lightweight and can be carried and maneuvered easily by a single installer without suffering from the fatigue of lifting heavy Rockwool boards, which may require two installers per board, or smaller board sizes.

R-Value Thermal Performance

It’s hard to beat the thermal performance of polyiso. At R6 per inch, it’s one of the best thermal insulation options for walls. With polyiso products like Rmax Durasheath® building envelope insulation, you can achieve an R21.8 with just 3-½” thickness, whereas achieving this same R-value with Rockwool Comfortboard 80 requires over 5” thickness.

Affordability

Polyiso insulation is affordably priced at just over a dollar per square foot for a two inch thickness. Rockwool, on the other hand, can be quite pricey at nearly two dollars per square foot at the same thickness. Since you’re getting less thermal insulating power for the same thickness, that’s a double whammy.

Availability

Polyiso is more readily available for purchase by ordinary homeowners, because it is available at building supply stores. Rockwool Comfortboard 80, on the other hand, can be a specialty item that is not stocked in stores and often requires a special order and larger quantities.

Tailored Performance

Polyiso has a unique advantage over most other wall insulation types, including Rockwool Comfortboard 80—it can be tailored to meet your project’s needs by applying an appropriate facer. Because polyiso not only accepts, but requires a facer during production, it gives you the choice between different performance properties that you want to incorporate.

For example, if you’re looking for an air and vapor barrier, you can find an all-in-one solution with Rmax’s ECOMAXci® FR Air Barrier. Rockwool, on the other hand, is vapor permeable and requires a second product to add vapor protection.

Here are more polyiso insulation products that are available as an alternative to Rockwool Comfortbatt 80:

ECOMAXci® FR Ply: Fire-Resistant Plywood Faced Polyiso for Cladding Attachment

R-Matte® Plus-3: Aluminum faced polyiso available at your local big box retailer

Thermasheath®: Reinforced aluminum faced polyiso boards

Thermasheath®-SI: Structural composite insulation with aluminum facers

Find the Perfect Insulation for Your Next Project with Rmax

Rmax has been in the insulation business for decades and has honed and perfected its evolving product line to meet building codes and customer needs. We have a full lineup of insulation solutions to help you meet your project’s requirements and get your next job started off on the right foot.

Talk with one of our experts today today to get help choosing the right insulation for your project!

Maximizing Thermal Efficiency: Unlocking the Potential of Under Slab Insulation

Mineral Wool Insulation: Advantages, Disadvantages, and a Superior Alternative

Exploring alternatives to traditional building materials is a critical part of the construction process. Should you continue to use what you know has worked in the past, or is there something better out there? If you’re considering mineral wool insulation for your next project, it’s time to evaluate the pros and cons and know your options.

What is Mineral Wool Insulation?

Mineral wool insulation is a building material used in construction to thermally insulate the building envelope as an alternative to fiberglass insulation. Builders realize the benefits of mineral wool insulation over fiberglass in several areas, including:

Higher R-Value

Better Acoustic Blocking

Superior Fire-Resistance

Like fiberglass, mineral wool typically comes in batts, but carries a little more stiffness and dimensional stability than fluffy fiberglass batts or rolls.

What is Mineral Wool Made From?

The minerals in mineral wool can come from volcanic rock as a raw material source. Another common raw material used to make mineral wool is called slag, a byproduct of molten metal production. Slag is a mixture of impurities and flux that escape the molten mixture during the melting process.

The raw materials in mineral wool are spun into fibers, glued, pressed, and formed together—to create cotton candy-like wool batts that can be installed in areas of the building envelope, like the cavities between studs in a stud wall.

Advantages and Disadvantages of Mineral Wool Insulation

When selecting the right type of insulation for your project, it’s important to weigh the pros and cons of each material. Let’s cover the advantages and disadvantages of mineral wool insulation.

Installation

Mineral wool is stiffer than fiberglass, which makes it easier to cut with precision and install to fit a space perfectly. On the other hand, since the material is much more dense than fiberglass, it is also much heavier. This can make the installation process a little more challenging due to the added weight of the material.

Thermal R Value

In terms of insulating value, mineral wool carries an R-value of just above R4 per inch, meaning that it requires 3.5” to achieve R15. It is an improvement over fiberglass, which carries an R-value of under R3 per inch, for an R13 at the same thickness of 3.5”.

When space matters, mineral wool carries a slight edge on thermal performance over fiberglass with the added benefit of enhanced sound blocking. However, there are other insulation options on the market today that provide significantly higher thermal insulating values than mineral wool.

Price and Availability

Mineral wool is more expensive than fiberglass and it can be more difficult to procure with fewer options available at local contractor supply warehouses. However, mineral wool can be tailored during the manufacturing process to meet specific needs and is available in various options, including:

Soundproofing

Fire-resistant

Fire and Sound

Increased Thermal Performance

Other types of insulation can introduce additional properties, but it’s generally the facer that is changed rather than the insulating material itself. Mineral wool is unfaced.

An Alternative to Overcome the Disadvantages of Mineral Wool Insulation: Polyiso

The disadvantages of mineral wool include price, availability, lackluster thermal performance, and limited installation applications. If you’re looking for an alternative to mineral wool, polyiso is a valid consideration. Unlike mineral wool, polyiso is a rigid foam insulation—so it is both lightweight, and easy to work with.

Polyiso comes in boards that can be cut to fit by hand. The modular sizing makes installation fast and easy, to decrease your cost of labor. Polyiso is also widely available from manufacturers in various thicknesses ranging from ½” up to 6” and it can be doubled up in multiple layers to meet thermal R-values with ease.

Polyiso outperforms mineral wool in thermal performance with a steady R6 per inch for polyiso. That means it only requires 2.5” of polyiso insulation like Rmax Durasheath® to meet R15, while it takes 3.5” of mineral wool.

When it comes to installing wall insulation, why limit yourself to the wall cavity or to using expensive furring to hold mineral wool in place? With polyiso, you can achieve continuous insulation on the outside of the stud cavity simply by fastening the insulation directly to your walls underneath your cladding.

You can also turn your continuous insulation into an air and vapor barrier with inventive polyiso products like the ECOMAXci® FR Air Barrier, which has glass fiber reinforced aluminum facers to limit moisture and vapor permeance, as well as air flow.

Rmax Can Help You Decide Which Insulation Solution is Best For Your Project

While there are some clear benefits of mineral wool insulation, there are an equal number of drawbacks. Get help choosing the right products for your next build by reaching out to the experts in insulation. We can help you pick a solution that meets your design criteria and fits within your budget.

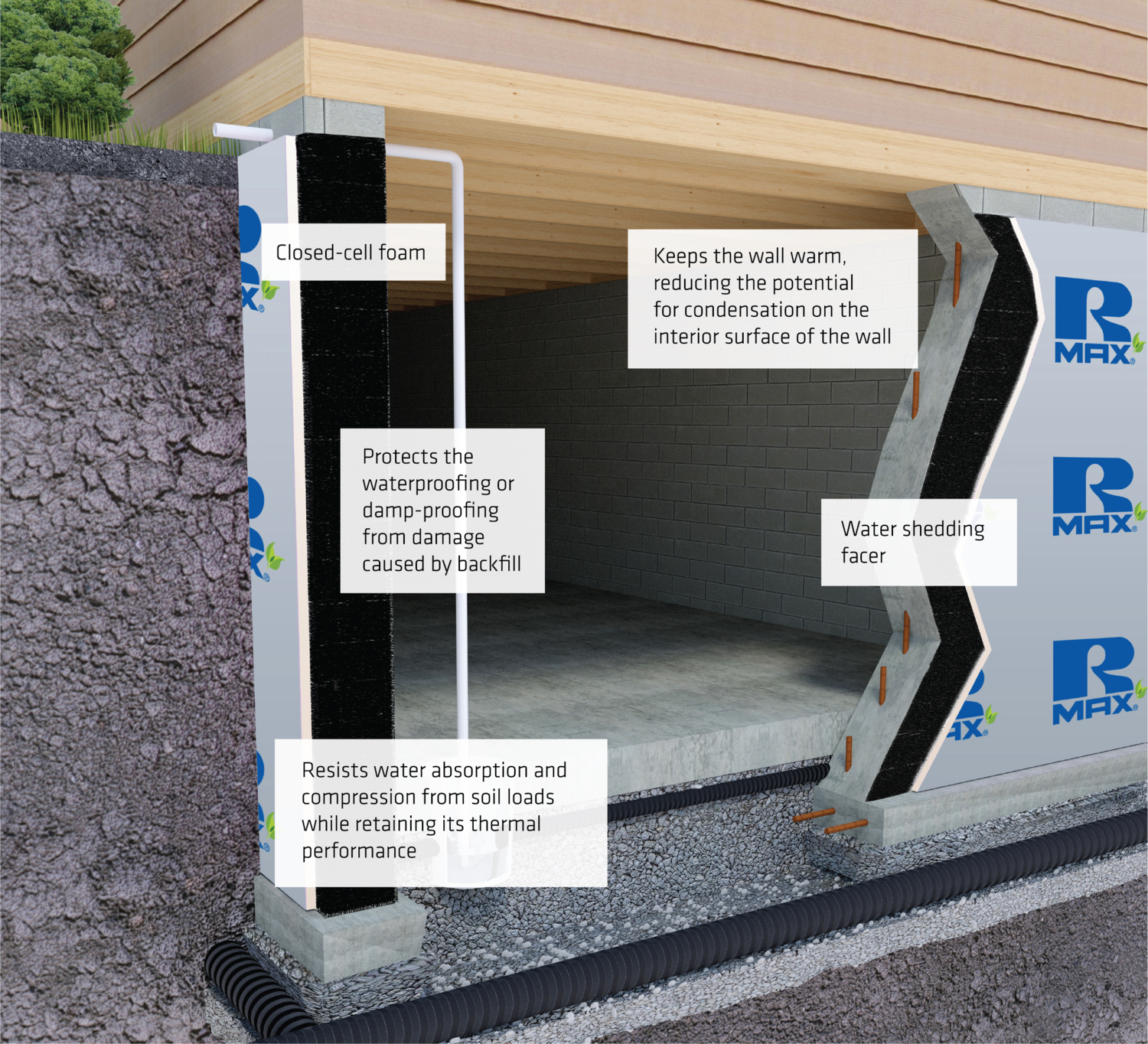

The Best Option for Exterior Foundation Insulation Panels

Insulation isn’t just for thermal comfort. When it comes to insulating your building envelope, it goes beyond the roof and walls above grade. Your foundation needs insulation, too. What exactly is required from below-grade foundation insulation panels? In this article, we’ll explore why you need to insulate a building’s foundation and what your options include.

Why Insulate Your Foundation?

Your project’s foundation needs to be protected in the same way as the rest of the building that you see above ground. Things that you need to protect your building envelope from include:

Moisture

Extreme temperatures

Water intrusion

Common problems that building owners face that can be solved by proper insulation at the foundation level include mold, mildew, water intrusion, and shifting of structural elements. When you use foundation insulation panels, you can minimize or eliminate these issues.

Eliminate Condensation

Exterior foundation insulation panels can reduce or eliminate condensation problems. Condensation happens when warm air drops in temperature quickly and the moisture condenses on a cold surface. If your walls are cold and your home is warm, you’ll have an increased risk of condensation problems. Installing exterior foundation insulation panels keeps your walls warm to match your interior space’s temperature.

Protect Your Structure

The freeze-thaw cycle can wreak havoc on buildings. Over the course of a year, most structures will experience extreme temperature variations, leading to the expansion and contraction of each of the building components. Extreme temperature fluctuations can lead to shifting, settling, and other problems in your structure. Protect your structure by shielding it from direct contact with these extreme changes in temperature with exterior foundation insulation panels.

Keep Water Out

Water flows through the path of least resistance. Since a building’s foundation creates a large hole in the earth that displaces soil and water, water will always try to get back in. That’s why waterproofing your foundation is so important. Applying waterproofing materials alone to your basement walls will not be sufficient. Because your waterproofing gets backfilled with soil, you’ll need to protect it. Foundation insulation panels an inch or so thick can do the trick, by ensuring that your waterproofing remains untouched andis able to do its job by keeping the water out of your building’s below-grade floors.

What Type of Insulation to Use on Exterior Foundation Walls?

Exterior insulation comes into contact with the elements directly, so you’ll want to make sure you’re using a compatible building material that will not be destroyed or hindered in the unpredictable below-grade environment. Using board insulation, such as XPS, EPS, or Polyiso—that was manufactured in a controlled environment is essential to making sure you’re applying a consistently high-quality layer of foundation insulation. Plus, it’s quick and easy to install with its modular form.

When comparing good, better, and best options for exterior foundation insulation panels, it ranks like this:

Good: Expanded Polystyrene Insulation (EPS)

Better: Extruded Polystyrene Insulation (XPS)

Best: Polyisocyanurate (Polyiso)

The rationale behind this comes from looking at the moisture absorption properties of each insulating material. EPS performs the worst with a water absorption of 2% or more, XPS is better with a moisture absorption of .3%, and polyiso takes the cake with a water absorption of less than .2% when choosing a foil-faced version.

Superior Foundation Insulation Panels

When shopping for exterior foundation wall insulation, you’ll want a product that will last. Polyiso has many more advantages when it comes to insulating foundation walls. It’s versatile, durable, affordable, and readily available.

Rmax Thermasheath® is a premium foil-faced polyiso insulation used in new construction and renovation projects for exterior foundation insulation panels. It can be placed in conjunction with foundation waterproofing on below-grade exterior walls and with concrete foundations. With an impressive R-Value of R6 per inch, you can achieve high energy efficiency with minimal thickness while still providing protection to your foundation and waterproofing.

Rmax Thermasheath can be used as a Water-Resistive Barrier (WRB) when used together with construction tape at the joints. Polyiso is versatile because it is compatible with multiple attachment methods, including adhesives or mechanical fasteners.

Tapes that are compatible with Rmax Thermasheath® include R-SEAL 3000 and R-SEAL Construction Tape. R-Seal 3000 is an aluminum foil-coated tape with pressure-sensitive adhesive that makes it extremely resistant to humidity, moisture, and mold. R-SEAL Construction tape is a durable mold, moisture, and UV-resistant BOPP film with pressure-sensitive acrylic adhesive.

Rmax Can Help with Your Next Construction Project

Neglecting to insulate a building’s foundation can lead to structural problems, heat loss, moisture issues, and more. Before you break ground on your next construction project or remodel, give your local Rmax representative a call to make sure you’re utilizing the right types of insulation throughout your entire building envelope. From below grade—up to the roof—and everywhere in between, we can provide the best solutions.

Contact us today for advice from the insulation experts!

Mineral Wool Insulation vs. Fiberglass and a Better Alternative

In a world where there are endless choices in every market, construction is no different. It can make picking the right building materials for your next project feel like a spiral of endless decisions. One choice that you’ll need to make when designing your building envelope is which insulation to use.

If you’re asking, “What is the difference between mineral wool and fiberglass insulation?,” we’ve got the answer.

What is the Difference Between Mineral Wool and Fiberglass Insulation?

Before comparing mineral wool insulation to fiberglass, let’s define the basic properties of each insulating material by itself.

Fiberglass Insulation

Made from tiny glass threads that are spun into fibers resembling cotton candy, fiberglass insulation is a popular insulating material used in home construction projects.

You’ll see it loosely stuffed into stud wall cavities to fill the gaps and give a little thermal insulating value. It is flexible and can fit around irregular shapes, but it loses some thermal value if it’s compressed. It needs to stay fluffy in order to work, and it’s not self-supporting.

When packaged, fiberglass insulation typically comes in rolls or batts, with widths based on common stud spacing increments. Fiberglass insulation is a staple in home improvement stores and it is easy to find locally.

Mineral Wool Insulation

Mineral wool insulation is made in a similar way to fiberglass, but with different raw materials. Rather than glass, mineral wool uses molten rock or other minerals that are spun into a cotton candy-like blanket with additives. Like fiberglass, the fibers are then compressed and heated.

Mineral wool is a less common insulating material in homes, but is used more often in commercial applications, including wall cavities. Mineral wool insulation is heavier and more dense than fiberglass insulation, which makes it a little more difficult to work with. It can be purchased in large batts or boards.

Comparing Fiberglass vs. Mineral Wool Insulation

Fiberglass insulation and mineral wool insulation have a similar manufacturing process and both come out looking a lot like cotton candy. Let’s compare some performance specs:

Thermal R-Value

When comparing mineral wool to fiberglass insulation in thermal performance, mineral wool takes the cake. With an R-value of up to R15 for 3.5” mineral wool, it beats fiberglass by a couple of points at this depth. Fiberglass insulation has an R-value of about R13 at 3.5” thick.

Installation

Fiberglass and mineral wool insulation are both installed by loose-laying batts into stud wall cavities, and can be cut by hand with ease. Mineral wool requires an insulation knife and fiberglass insulation requires a utility knife with a straight edge.

Moisture Resistance

When comparing the moisture resistance of fiberglass insulation to mineral wool, there is a clear winner. Mineral wool is naturally moisture-resistant since it’s made of rock or slag fibers. Fiberglass insulation is more prone to water absorption—and if it gets wet, it creates an environment where mold growth is uninhibited.

Fire Resistance

In a fire, it’s critical that your insulation works to extinguish the flame rather than fuel the fire. When comparing mineral wool batt insulation to fiberglass, fiberglass is less fire resistant than mineral wool. Mineral wool has zero flame spread and no smoke when exposed to fire. Fiberglass, especially when using a kraft paper facer can both create smoke and spread the flame.

Cost and Availability

When it comes down to purchasing your building materials, cost and availability are important considerations. When looking at mineral wool insulation vs. fiberglass cost, fiberglass is less expensive and more readily available.

A quick search from a local big box store gave the following results:

Availability and Cost of Mineral Wool vs. Fiberglass Insulation

A Superior Alternative to Fiberglass and Mineral Wool

Fiberglass and mineral wool insulations are both good building materials, but there are superior options on the market today that outperform both of these choices.

Polyisocyanurate (aka polyiso) is a rigid foam board insulation that can be used as an alternative to fiberglass or mineral wool.

Here’s how polyiso stacks up against mineral wool vs. fiberglass insulation:

R-Value

At 3.5”, Rmax Thermasheath Polyiso® carries a thermal value of R23.9, that blows both fiberglass and mineral wool out of the water. It takes just 2” of polyiso to match the thermal properties of 3.5” thick mineral wool or fiberglass.

Installation

Polyiso is as simple to install as fiberglass and mineral wool, but has with the added versatility of being able to use it as a continuous insulation under cladding on exterior walls.

Moisture and Fire Resistance

Foil faced polyiso acts as an air and water vapor barrier when installed continuously—an option that is unavailable for batt insulations.

Cost and Availability

Polyiso is priced at around $1.00 per square foot for R13.1 (2” thick) from local home improvement stores and can be found more readily available from contractor suppliers.

Choose Rmax Polyiso For Your Next Project

Rmax has been in the insulation business for decades. We know our insulation and we can share our knowledge with you on your next project.

Let our experts help you find the right wall insulation for your next project. Reach out to your local Rmax representative today!

Shielding Your Project: Discover the Best Air, Water, and Weather-Resistant Insulation

The purpose of buildings is to provide shelter from the elements, such as wind, water, and protection from extreme temperatures.

Simple buildings with empty stud walls without any guts won’t necessarily provide much thermal comfort for the occupants though. Consider a storage shed that provides protection from overhead precipitation—but is usually quite uncomfortable, thermally speaking.

In order to get thermal comfort, you’ll need a good seal around the building envelope. That’s where air and water barriers come in.

Air and Vapor Barriers in Walls

Air barriers are a building component that helps limit the unintended flow of air into your building. Think of a drafty window in the winter. The cold air blowing in reduces thermal comfort. It’s the air barrier’s job to eliminate air movement through your walls.

A secondary function of many air barriers is that they can also act as a vapor barrier, by limiting the transmission of moisture through your walls. In this case, these building components are called air and vapor barriers. Air barrier insulation systems are an essential component in construction since excess moisture inside your structure can cause serious problems like condensation, high humidity, and mold growth.

How is an Air and Vapor Barrier Installed?

Air and vapor barriers come in many forms, including rolls, liquids, boards, and more. Here are a handful of the common air and vapor barriers you’ll see on jobsites:

Plastic Sheeting Film

Peel & Stick Membranes

Liquid Paint (Roll-on)

Liquid Coating (Spray-applied)

Spray-foam Insulation

Foil-faced Insulation Boards

Many air and vapor barrier options require a specialized trade contractor to install the air barrier onto an insulated wall system. For example, the peel and stick will require the insulation contractor to finish installing first, so that he can then apply the air and vapor barrier to the insulation.

Make It Part of Your Wall

Not all air barriers are also vapor barriers. Some air barriers allow moisture to permeate through. Likewise, some vapor barriers allow air to pass through. As you select your air and vapor barrier, make sure you’re picking a material for your design that will limit both air and water movement, and will also provide weather protection for your project.

Don’t let air and vapor barriers be an afterthought in your project. Instead, build your wall system to incorporate thermal performance (high R-values) while also optimizing air and vapor barrier technology. Luckily, there is a product for this application that works as a three-in-one: air barrier insulation systems.

Air Barrier Insulation Systems vs. Air Barriers

Many air barriers require the coordination of multiple trades to install a complete wall system. However, that’s where air barrier insulation systems are different. Insulation air barriers take two wall components and combine them so that they can be installed in a single pass by a single contractor. This saves on labor and shortens your construction timeline.

Rmax’s Water Vapor Barrier Insulation Solution

You’re already installing insulation, so why not turn your insulation’s facer into an air and vapor barrier? The ECOMAXci® Wall Solution combines Rmax’s premium insulation with an air barrier facer that combines high thermal performance with air and vapor performance to craft superior walls that maximize thermal efficiency.

The ECOMAXci® Wall Solution works like this:

Install ECOMAXci® FR Air Barrier foil-faced thermal insulation boards on your wall surface.

Treat joints and penetrations with either liquid flashing or tape flashing.

Benefits of ECOMAX® FR Air Barrier Wall Solution

The specs of the ECOMAXci® FR Air Barrier speak for themselves when it comes to performance. With an R 6.5 per inch, it maxes out the thermal performance capabilities of building insulation.

Check out the specs on the ECOMAXci® FR Air Barrier:

ECOMAXci® FR Air Barrier Specifications

Beyond the high R-value per inch, insulation air barrier systems have many advantages over traditional air and vapor barriers.

Take a look at more ways that ECOMAXci® FR Air Barrier can benefit your next project:

Eliminates the need for exterior gypsum

Eliminates the need for building wraps

Reduces coordination requirements between contractors

Reduces labor by installing air barrier and insulation at once

Lighter and easy-to-manage materials

Less-specialized installation

Provides continuous insulation

Rmax Brings You Solutions That Perform

Build your next project with innovative solutions that save on construction time and labor costs while also contributing to a higher-performing envelope. Rmax can help you pick the right weather resistant insulation and accessories that work with your budget and design priorities. Reach out to your local Rmax representative today for guidance on your next job!

Common Problems with Polystyrene Insulation Board and a Better Alternative

As you browse building materials for your construction project, you may become overwhelmed with decision paralysis, especially when choosing between different types of insulation. The key to making the right choice is to broadly narrow down your options as far as possible, and then do a thorough comparison on the remaining few.

If that’s where you’re at—you’ve narrowed down your selection to a few options, and you’re faced with choosing between polystyrene and polyiso board insulation—we can help.

Let’s cover the basics, first.

What is Polystyrene Insulation Board?

Polystyrene is a plastic-based polymer that is used to create polystyrene foam board insulation. In its raw form, polystyrene looks like small plastic beads. The polymer beads can be manipulated with heat and blowing agents to encapsulate air and other gasses to manufacture two major types of foam insulation commonly used in construction today: extruded polystyrene (XPS) and expanded polystyrene (EPS).

Extruded Polystyrene

Extruded polystyrene is commonly called XPS, blue board, or pink board. XPS is made with polystyrene beds that are melted, compressed, and extruded into board shapes of varying sizes. Extruded polystyrene rigid insulation board is used in everyday construction; it’s often found in below-grade applications.

Expanded Polystyrene

Expanded polystyrene is called EPS, or beadboard, in construction lingo. EPS is made by using steam to expand and inflate the polystyrene pellets. The expanded pellets are then placed in molds and steam-fused together. After that, they cool and are cut to custom sizes. Expanded polystyrene board insulation is used in construction throughout the entire building envelope.

Disadvantages of Polystyrene

When comparing polystyrene to other building materials, such as polyisocyanurate board insulation, it’s important to consider weaknesses. Here’s where rigid polystyrene insulation boards fall short:

Limited Service Temperature

Polystyrene is a thermoplastic material, meaning it can become malleable and will melt above a certain temperature. Both extruded and expanded polystyrene have a maximum service temperature of about 165 degrees Fahrenheit.

Since building envelope surface temperatures commonly exceed this temperature in the summer months, that could mean disaster for polystyrene foam board insulation.

Low Melting Point

The type of building materials you choose can have a big impact on how well your structure can survive a devastating event like a fire. With its low melting point, polystyrene insulation can pose a higher risk than other building materials during a fire.

Rather than being fire-resistant or fire-retardant, polystyrene melts when exposed to flame. The liquified material can drip and spread fire to other parts of the building.

R Value

Thermal resistance, or R-value, is a key consideration when choosing your insulation.

Higher R-values mean that your insulation works better to keep temperatures stable inside your building. A higher R-value per inch means that you can achieve the same code performance level with less material. Polystyrene insulations carry an average R-value of around R4 or R5 per inch, varying slightly depending on the type and density used. This is a middle-of-the-road value and there are better insulators than polystyrene board insulation if you need a higher R-value per inch for your project.

Water Permeance and Absorption

Insulation that absorbs water can compromise the insulating value and can lead to mold and other problems over time. Expanded polystyrene insulations have water absorption of between 2-4%. Surprisingly, this is higher than other types of insulation, which can achieve less than 1% water absorption. Similarly, water vapor permeance measures whether vapor can pass through the insulation.

Expanded rigid polystyrene board insulations carry a water vapor permeance of between 2.5 to 5 perms, which allows vapor to pass through at a higher rate than extruded polystyrene or polyiso.

Polyiso Instead of Polystyrene

Now that we’ve covered some of the shortcomings that come with polystyrene board insulation, let’s introduce a better solution—polyiso.

Here’s why polyisocyanurate, or polyiso, is superior to polystyrene. The service temperature of polyiso is nearly double that of polystyrene. Polyiso can be installed in applications up to 250 degrees Fahrenheit. Additionally, polyiso does not melt at high temperatures or when exposed to flame. Instead, it chars.

Thermal performance is another area where polyiso is the clear winner when compared to polystyrene rigid insulation board. Polyiso has an R-value of R6 per inch, which is a significant metric when you need to insulate narrow spaces like wall cavities.

Finally, when it comes to water resistance, polyiso again outperforms expanded polystyrene. Water absorption of polyiso sits at less than 1% volume and water vapor permeance at less than 1.5 perms.

Find the Best Polyiso Insulation Solutions with Rmax

Choosing between rigid polystyrene insulation board and polyiso becomes easier when you have all the facts. Are you ready to make the call and specify your building’s insulation? Rmax can help you choose the best polyiso for your next project. Reach out to your local representative to get started!

The Best in Insulation: Understanding Sustainable Rigid Insulation

If you’re going green on your next construction project, you’ll need to know what your options are when it comes to sustainable rigid insulation. In this article, we cover common types of rigid foam insulation, which ones are most sustainable in building construction, and why.

Types of Rigid Foam Insulation

You have choices when it comes to selecting a suitable rigid foam insulation board for your building’s walls, foundations, and the rest of the envelope. Here are the three common foam board insulation types used in construction:

Extruded Polystyrene (EPS)

Expanded Polystyrene (XPS)

Polyisocyanurate (Polyiso)

Of these, polyiso is the most environmentally friendly. Let’s find out why.

Sustainability Factors

To determine whether a building material is sustainable, we need to get more specific about what makes something sustainable. We’ll use LEED (Leadership in Energy and Environmental Design) to help us define sustainability. LEED is a certification system developed by the U.S. Green Building Council that rates buildings based on their impact on the environment.

There are multiple routes to achieve LEED certification for your building, but here are the primary goals to focus on when it comes to choosing sustainable building insulation.

Increase Energy Efficiency

Reduce Impact on Environment

Promote Sustainable Material Cycles

How to Source Sustainable Rigid Insulation

How do you put those goals into action and find the most sustainable rigid insulation? Here’s what to look for:

Raw Materials

When choosing your building insulation, take a look at the raw materials used to manufacture the product. Polyiso, EPS, and XPS are all made from non-renewable petrochemicals. Currently, none of the foam insulation boards we use today are made from 100% renewable resources.

Renewable materials are the raw materials that replenish their own reserves quickly, such as those materials derived from quick-growing crops. They do not deplete the Earth’s natural resources, thus promoting more sustainable material cycles.

They may not always come in board form. Some examples of insulation types that are made from renewable raw materials include wool, cotton, and cork.

Recyclable

Foam board insulation isn’t made from renewable resources, but it is highly recyclable. All three types of foam insulation board can be recycled and reused at the end of their life cycle.

For example, when a building is remodeled, the existing insulation can be removed and reused on other projects. The facers on polyiso can also be recycled up to 100%.

Manufacturing Process

When selecting a sustainable rigid insulation for your project, take a look at how the insulation is made and what the impact of that process is on the environment. New technologies are allowing for more sustainable manufacturing processes and better blowing agents for foam insulation boards.

Look for a product that uses environmentally friendly manufacturing processes. Rmax polyiso uses third-generation blowing agents that produce zero ozone depletion. All Rmax polyiso insulation boards are HCFC-free and CFC-free.

Performance

Insulation is unique when it comes to promoting sustainability because it creates a lasting effect. The more effective your insulation is at insulating your building, the more energy is conserved by the HVAC systems running inside.

The most sustainable rigid insulation is one with a high R-value that can be installed continuously without thermal breaks. Polyiso carries the highest R-value per inch when comparing the three board insulation types.

Durability

A building material that works great but ends up in a landfill five years later is not very sustainable. Rather, sustainable rigid insulation needs to last at least as long as the life of the building—if not longer, so that the energy expended in creating, transporting, and installing the material achieves maximum efficiency.

While all three foam board insulation types are reusable, polyiso is the most durable with its protective facers.

Local Impact

Consider the local impact on the environment when choosing sustainable rigid insulation. For example, if the manufacturing plant is closer to the jobsite, it requires less fuel and resources to transport the material to the construction site.

On the other hand, if your product is manufactured across the country or even across the ocean, it’s going to have a larger negative impact.

Clean Air

Our building materials can have a positive impact on the indoor environment, including the air we breathe and creating healthy spaces for occupants. Rmax is proud to have received Clean Air Gold Certification from Intertek Sustainability. This certification means that Rmax insulation products do not have VOC emissions that negatively impact indoor air quality.

Rmax Polyiso: Your Sustainable Rigid Insulation Solutions

Going green in construction is a noble cause, and simply by evaluating the environmental-friendliness of your envelope’s insulating materials, you can make a notable impact. For a complete review of how Rmax polyiso is a qualified sustainable rigid insulation, read more in our Rmax LEED Credits Worksheet.

Not sure which Rmax polyiso product is right for your project? Reach out to your local Rmax representative for help!