Starting with the basics—your foundation is literally the most important part of your building. Without a sturdy and functional foundation, a building will shift, crumble, and become exposed to the unforgiving elements that can wreak a lifetime of havoc once inside.

It’s critical to protect your building’s foundation from the start, but did you know that insulating foundation walls on the exterior side is one way that you can proactively protect your structure? Since building codes require insulation on basement walls for climate zones three through eight anyway, why not maximize your investment by placing it on the exterior face of the wall?

There are many advantages to insulating the exterior side of the foundation walls:

Protection

Your foundation needs protection from the elements. Using waterproofing along with foundation wall insulation can substantially preserve your building’s foundation. Start by designing a comprehensive wall section.

This means that you’ll incorporate waterproofing and protection board in addition to the structural components like concrete or masonry that you find in standard foundation walls. The added layers help keep water out.

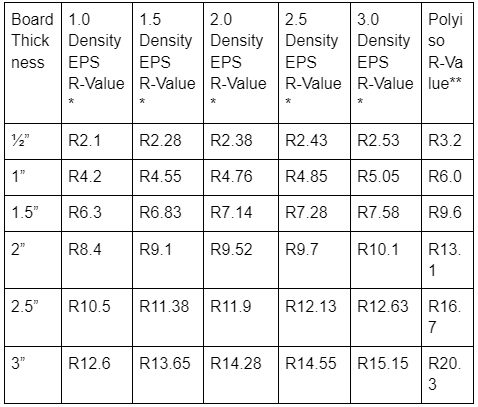

Additionally, the foundation foam insulation on the exterior side provides a buffer zone of protection for your newly installed waterproofing from backfilled soil. This protection layer typically consists of one or two inches of foam board like extruded polystyrene or polyiso.

Cost Savings

When you design your foundation walls, keep in mind that you can save on building materials by moving the foundation wall insulation to the exterior side. That’s because insulating foundation walls from the outside doesn’t require an expensive finish on top. Instead, the exterior-facing insulation is backfilled and covered by soil.

Increase Useable Area

Insulating your foundation on the exterior side of the wall cavity increases the building’s usable square footage because the insulation doesn’t encroach upon the interior space. This results in a lower price per square foot and a higher value to the occupants. It may seem insignificant, but consider a 10’x10’ room with 2” insulation on each wall. When insulated on the exterior, you get 100 SF, but if you insulated on the interior, usable square footage goes down to 93 SF.

In a building with fifteen rooms this size, you’ll lose an entire room’s worth of space just by insulating on the interior side of the foundation wall.

Energy Efficiency

When you insulate foundation walls, it’s important to consider whether the installation will be continuous. Traditionally, interruptions in insulation by studs or other components have been acceptable. However, continuous insulation is more widely specified in the latest building codes.

This installation style minimizes heat loss and provides increased energy efficiency for your HVAC systems. When you choose board insulation on the exterior side of the foundation wall, there are naturally fewer obstacles—which allows you to achieve continuous insulation effortlessly.

Freeze Thaw Protection

The freeze-thaw cycle that most regions in the U.S. experience throughout the seasons can inherently cause damage, including cracking and shifting, to your foundation.

Luckily, you can minimize the impact of the freeze-thaw cycle by insulating foundation walls on the exterior side, to provide a cushion that allows expansion and contraction as the Earth’s temperatures fluctuate. The insulation on your foundation also provides a thermal break so that extreme temperature gradients are not making direct surface contact.

Minimizes Condensation

Condensation happens when warm air, which holds moisture, cools quickly and can no longer hold the moisture—so it condenses into water droplets on a cooler surface. This often happens on foundation walls because the cool concrete or masonry holds its temperature while the air temperature rises.

This provides an environment where condensation is prone to forming. However, you can minimize or eliminate condensation in this area by installing foundation foam insulation boards on the exterior side to keep your foundation walls warm and reduce the drastic temperature variation that causes condensation.

Easy Install

Installing insulation can be time consuming and labor intensive, but it doesn’t have to be. When you move your insulation to the exterior side of the foundation wall, installation is a breeze. Simply tack modular boards to the outside of the foundation wall in a temporary manner until the soil is backfilled for permanent securement.

Exterior vs. Interior

Sometimes insulating the outside of the foundation wall is not practical. This is the case in many retrofit projects where the soil would need to be excavated around the building in order to install the insulation. Interior insulation is a more practical solution when you cannot easily access the outside vertical surface of the foundation.

Rmax Can Help You Pick the Right Insulation

Picking the right type of building materials can become a headache in a hurry, but it doesn’t have to be overwhelming.

Ask for help from the experts at Rmax, who know all about building insulation types, where to use them, and how to fit the right one into your budget. Our representatives can review your project’s design and help you pick the right insulation for the job. Get answers today by reaching out to your local Rmax representative!