When insulating your construction project, whether it’s your home, business, or a work-related endeavor, it’s important to consider all of your options so that you can make informed decisions about which materials will best suit your design’s expected thermal performance. Here, we break down one of those material options: EPS.

What is EPS Insulation?

Expanded polystyrene, or EPS, is a type of closed-cell insulation commonly used in walls, roofs, and foundations. The manufacturing process uses steam, blowing agents, and resin beads to create the final product. ASTM C578 is the standard specification for this type of thermal insulation.

One unique property that is inherently beneficial to EPS is its ability to be worked into shapes or molds during production. This makes it useful for very specific applications. Consider, for instance, the packaging material that comes around a new flat-screen TV or computer. It’s perfectly molded to support the shape of the product it’s meant to protect.

R-Value of EPS Rigid Insulation

When it comes to choosing the best insulation to cover a building envelope, it’s less about the shape of the material and more about its properties and performance. One measure to compare is the thermal resistance value, or R-value. A typical EPS insulation R-value stands firm at about R4 per inch of thickness. That means a one-inch thick board will have at least an R4 and a two-inch thick EPS board will have a minimum R8.

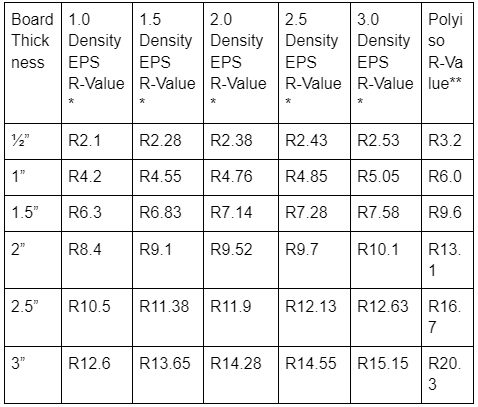

EPS is available in various densities, ranging from around 1-3 pounds per cubic foot (pcf), which in turn creates varying levels of compressive strength (from 10-60 psi). These factors impact thermal performance. Take a look at the EPS Insulation R-value chart below to check how the densities affect the R-value of EPS:

Typical EPS Insulation R-Value Chart

*Values based on Insulfoam unfaced EPS insulation at 40℉

As you can see, the R-value of EPS rigid insulation requires increasing thicknesses and/or densities in order to achieve a good thermal barrier. For example, if you want to meet the minimum R13 for walls, you’ll need at least 3” thick EPS. For an R20 wall, you’ll need 4” or more, depending on the density you select.

A Superior Alternative to EPS for Higher R-Values: Polyiso

Oftentimes, you just don’t have four inches to spare inside a wall cavity. So, if you’re looking for an alternative that packs more R-value per inch, one option is polyisocyanurate (polyiso).

R-Value of Polyiso Insulation

Polyiso insulation ranks well in terms of insulating power. With an R6 per inch, polyiso beats EPS insulation R-values by nearly two full points on the scale. That seemingly small difference can add up quickly when you’ve got limited space for your insulation to fit into. Below, you can find the typical R-values for polyiso when compared to EPS insulation.

Polyiso vs. EPS Insulation R-Value Chart

*Values based on Insulfoam unfaced EPS insulation at 40℉

**Values based on Rmax Thermasheath® Polyiso insulation

Comparison of Polyiso vs. EPS Insulation R-Values

Across the board, polyiso outperforms EPS in thermal R-values. As you can see above in the polyiso vs. EPS insulation r-value chart, you can achieve an R20 with just three inches of polyiso—that shaves off an entire inch of insulation thickness when compared to EPS. Find the entire range of polyiso R-values for Rmax products, including ECOMAXci® FR and Durasheath®, in our product R-value charts.

Get Help Selecting a Superior Insulation Board for Your Project

If you’re looking for ways to minimize insulation thickness without compromising on thermal resistance values, Rmax can help. Our representatives can help you pick the right product for your design. Whether you’re insulating a wall, roof, basement, or attic space, polyiso is a versatile and well-rounded building material used by professionals who build to last.

Contact one of our sales representatives today for more information!