The main purpose of insulation is to provide thermal comfort. While measuring thermal comfort can be somewhat subjective, there is a way to quantify thermal performance. By measuring thermal resistance, also known as R-value, we can see how different insulating materials perform.

Here, we look at the insulation R- for mineral wool and compare it to polyiso.

What is Mineral Wool?

Mineral wool is a building material that can be described as a cross between fiberglass and board insulation. It’s similar to fiberglass in its manufacturing process, where mineral fibers are spun into fluffy cotton-candy-like batts. However, mineral wool insulation is stiffer than typical fiberglass insulation and can come in modular board sizes, as we see with foam insulation—including polyiso, XPS, or EPS.

Mineral wool is produced from the minerals found in volcanic rock or even as a byproduct during steel production. Mineral wool is a more fireproof and soundproof option when compared to fiberglass, and carries a higher R-value.

What is R-Value?

R-value, or thermal resistance, is the measure of how well insulation does its job of preventing heat loss. A high R-value means that the material does a better job of blocking the flow of heat from one space to another. Generally, a thicker material will carry a higher R-value. So, two inches of insulation will have about double the insulating capacity of only one inch of the same material.

Building codes usually require specific R-values in new construction and remodel projects. The requirements can vary depending on your location, climate, and local ordinances. Typically, a minimum R-value is required for each aspect of the building envelope, including:

Roof or Attic Space

Exterior Walls

Slab on Grade

Check your local zoning office to determine your region’s building code requirements as you plan your project.

What is the R-Value of Mineral Wool Insulation?

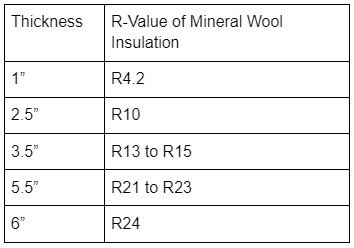

Mineral wool insulation R values are typically around R4 per inch. Below are some typical mineral wool insulation R-values for various thicknesses.

Mineral Wool Batt Insulation R Values

As you can see, 6 inch mineral wool insulation r-value comes in at R24. Regardless of thickness, mineral wool board insulation R-values consistently hover at around R4 per inch. If you’re using mineral wool alone to meet code, it will take you a significant thickness and weight of material to meet the R-values. The same R-values can be achieved with thinner and lighter materials, so it’s worth exploring alternatives such as polyiso.

Comparing Mineral Wool to Polyiso

When comparing rigid mineral wool insulation R-values to other types of material, R4 per inch is middle-of-the-road in thermal performance, considering that fiberglass insulation carries only R3 per inch. Polyiso steps up the R-value game with R6 per inch.

Take a look at typical R-Values for polyiso insulation in the table below.

R-Value Chart

The values listed in the R-value chart above match those of Rmax Durasheath® Polyiso, a foam insulation board approved for use throughout the building envelope, from wall cavities to ceilings and attics. It’s more than the R-value that makes polyiso different from mineral wool. Let’s cover some more of polyiso’s benefits.

The Many Benefits of Polyiso

Polyiso outshines mineral wool insulation in more aspects than thermal performance alone. Here are some more reasons polyiso is a great choice for the building envelope:

Versatility

Polyiso brings versatility to the table. Because polyiso requires a facer during the manufacturing process, it can work to your advantage. This allows customization of the properties you want your insulation to hold. For example, you can use aluminum foil-faced polyiso products such as Rmax Thermasheath® to provide enhanced performance where vapor and moisture are an element of concern.

Air and Vapor Barrier Capable

Mineral wool insulation is vapor permeable, clocking in at 35 perms. This means that air, vapor, and moisture can pass through the building envelope into your structure, unless a separate barrier is installed along with the mineral wool. Foil-faced polyiso products, on the other hand, allow less than .03 perms of air or vapor transmission. Building insulation products such as Rmax ECOMAX ci® FR Air Barrier contain impermeable polyiso that can double as a vapor retarder in walls when installed with proper tapes and details.

Find the Right R-Value Insulation For Your Project with Rmax

Thermal performance is why we’re here. If you’re shopping for the right type of insulation for your construction project, Rmax can help you find it. Whether you’re comparing the R-value of mineral wool insulation to polyiso or looking into other aspects, we’ll point you in the right direction.

Contact one of our experts today to get started!