In a world where there are endless choices in every market, construction is no different. It can make picking the right building materials for your next project feel like a spiral of endless decisions. One choice that you’ll need to make when designing your building envelope is which insulation to use.

If you’re asking, “What is the difference between mineral wool and fiberglass insulation?,” we’ve got the answer.

What is the Difference Between Mineral Wool and Fiberglass Insulation?

Before comparing mineral wool insulation to fiberglass, let’s define the basic properties of each insulating material by itself.

Fiberglass Insulation

Made from tiny glass threads that are spun into fibers resembling cotton candy, fiberglass insulation is a popular insulating material used in home construction projects.

You’ll see it loosely stuffed into stud wall cavities to fill the gaps and give a little thermal insulating value. It is flexible and can fit around irregular shapes, but it loses some thermal value if it’s compressed. It needs to stay fluffy in order to work, and it’s not self-supporting.

When packaged, fiberglass insulation typically comes in rolls or batts, with widths based on common stud spacing increments. Fiberglass insulation is a staple in home improvement stores and it is easy to find locally.

Mineral Wool Insulation

Mineral wool insulation is made in a similar way to fiberglass, but with different raw materials. Rather than glass, mineral wool uses molten rock or other minerals that are spun into a cotton candy-like blanket with additives. Like fiberglass, the fibers are then compressed and heated.

Mineral wool is a less common insulating material in homes, but is used more often in commercial applications, including wall cavities. Mineral wool insulation is heavier and more dense than fiberglass insulation, which makes it a little more difficult to work with. It can be purchased in large batts or boards.

Comparing Fiberglass vs. Mineral Wool Insulation

Fiberglass insulation and mineral wool insulation have a similar manufacturing process and both come out looking a lot like cotton candy. Let’s compare some performance specs:

Thermal R-Value

When comparing mineral wool to fiberglass insulation in thermal performance, mineral wool takes the cake. With an R-value of up to R15 for 3.5” mineral wool, it beats fiberglass by a couple of points at this depth. Fiberglass insulation has an R-value of about R13 at 3.5” thick.

Installation

Fiberglass and mineral wool insulation are both installed by loose-laying batts into stud wall cavities, and can be cut by hand with ease. Mineral wool requires an insulation knife and fiberglass insulation requires a utility knife with a straight edge.

Moisture Resistance

When comparing the moisture resistance of fiberglass insulation to mineral wool, there is a clear winner. Mineral wool is naturally moisture-resistant since it’s made of rock or slag fibers. Fiberglass insulation is more prone to water absorption—and if it gets wet, it creates an environment where mold growth is uninhibited.

Fire Resistance

In a fire, it’s critical that your insulation works to extinguish the flame rather than fuel the fire. When comparing mineral wool batt insulation to fiberglass, fiberglass is less fire resistant than mineral wool. Mineral wool has zero flame spread and no smoke when exposed to fire. Fiberglass, especially when using a kraft paper facer can both create smoke and spread the flame.

Cost and Availability

When it comes down to purchasing your building materials, cost and availability are important considerations. When looking at mineral wool insulation vs. fiberglass cost, fiberglass is less expensive and more readily available.

A quick search from a local big box store gave the following results:

Availability and Cost of Mineral Wool vs. Fiberglass Insulation

A Superior Alternative to Fiberglass and Mineral Wool

Fiberglass and mineral wool insulations are both good building materials, but there are superior options on the market today that outperform both of these choices.

Polyisocyanurate (aka polyiso) is a rigid foam board insulation that can be used as an alternative to fiberglass or mineral wool.

Here’s how polyiso stacks up against mineral wool vs. fiberglass insulation:

R-Value

At 3.5”, Rmax Thermasheath Polyiso® carries a thermal value of R23.9, that blows both fiberglass and mineral wool out of the water. It takes just 2” of polyiso to match the thermal properties of 3.5” thick mineral wool or fiberglass.

Installation

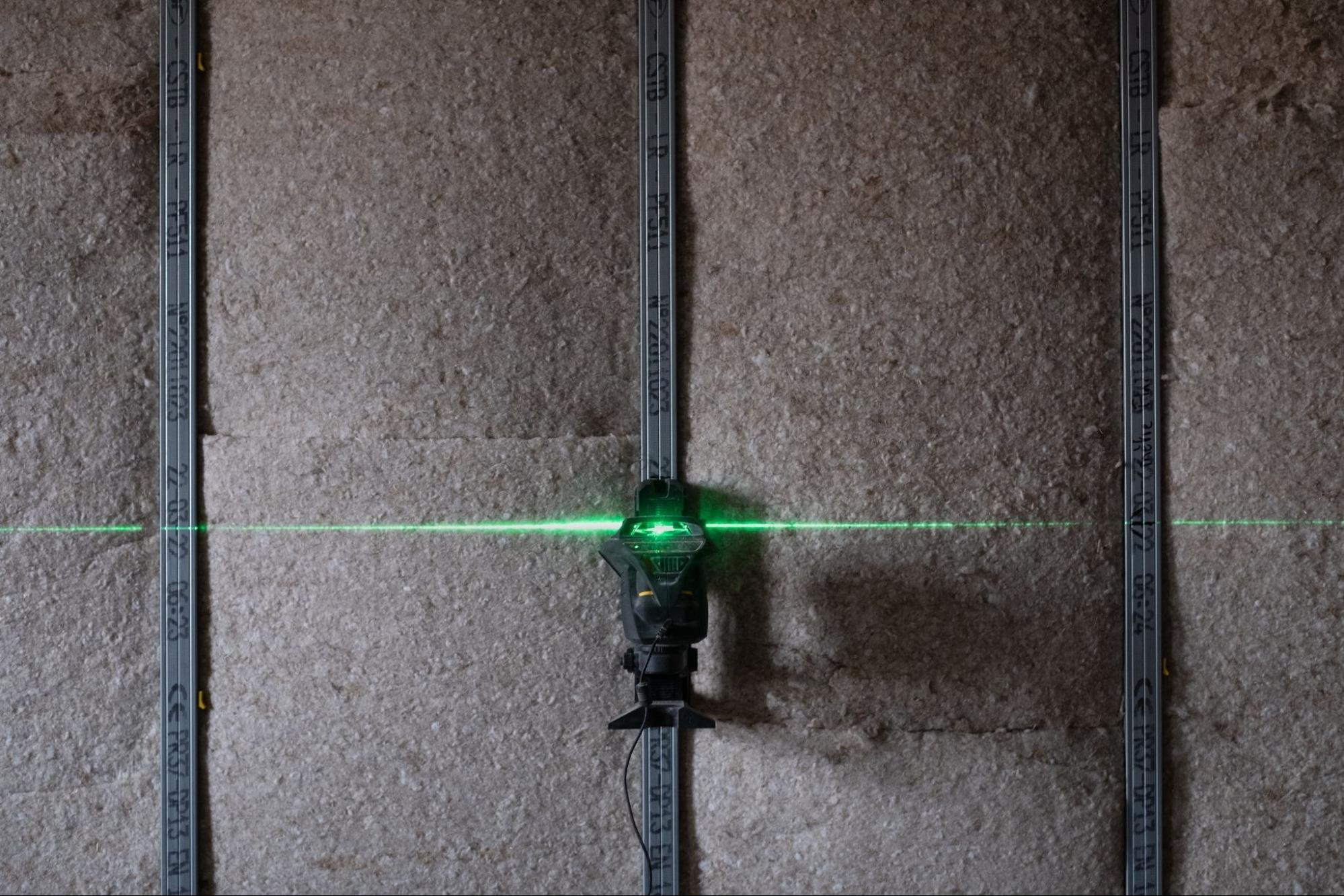

Polyiso is as simple to install as fiberglass and mineral wool, but has with the added versatility of being able to use it as a continuous insulation under cladding on exterior walls.

Moisture and Fire Resistance

Foil faced polyiso acts as an air and water vapor barrier when installed continuously—an option that is unavailable for batt insulations.

Cost and Availability

Polyiso is priced at around $1.00 per square foot for R13.1 (2” thick) from local home improvement stores and can be found more readily available from contractor suppliers.

Choose Rmax Polyiso For Your Next Project

Rmax has been in the insulation business for decades. We know our insulation and we can share our knowledge with you on your next project.

Let our experts help you find the right wall insulation for your next project. Reach out to your local Rmax representative today!