Building codes are the rules that everyone involved in construction—from architects and contractors to building owners—are legally obligated to follow. They are set at the local level, but national and global guidelines are also adopted as models.

This set of rules covers everything from how tall your building can be to which way your doors must open. Understanding building code requirements is critical because it can affect everything about your building’s design. For instance, insulating R-value (thermal resistance) requirements in your building’s envelope will determine the thickness of your walls. This impacts which materials you’ll select to meet the code requirement and fit with your design intent.

It can be challenging to stay informed on new and changing building codes. So, before you begin building that new home or commercial structure in Texas, you’ve got to know the laws. This article helps you do that by sharing the need-to-know on building code insulation requirements in Texas.

Reviewing Codes Before You Build in Texas

Building codes must be reviewed—before permitting, procurement, or picking up a hammer. It’s during the design phase that building codes should first be taken into account. Codes can vary based on your geographical location, so every building may have different requirements. For the purpose of this article, we will focus on the larger geographical regions inside Texas. However, you will need to consult your local government (city or county) about local building codes for your area.

The International Code Council (ICC) sets performance standards for building envelope energy efficiency. The ICC created the IECC (International Energy Conservation Code) to set the standard for building codes related to energy efficiency for residential and commercial structures. This code contains zoning maps that divide the U.S. into different climate zones based on temperature, humidity, and rainfall. Texas is currently operating under the 2015 IECC for both residential and commercial, effective since 2016.

Inside Texas, there are three climate zones, according to the IECC Climate Zone Map. They include:

Zone 2: Southern Texas

Zone 3: Central Texas

Zone 4: Northwest Texas

In 2021, a new map was released that added additional climate zones. Once adopted, Texas climate zones will include:

1A: Southern Tip of Texas—Very hot and humid

2A: Southeast Texas—Hot and humid

2B: Southwest Texas—Hot and dry (humid below the line)

3A: Northeast Texas—Mixed and humid

3B: West Texas—Hot and dry

4B: Northwest Texas—Mixed dry

Once you have identified the climate zone that your building will be located inside, you can find out which insulation code requirements apply to your Texas building.

Residential Insulation Code Requirements in Texas

According to EnergyStar.gov, insulation code requirements for Texas homes depend on the geographical region the building is located in. Here’s a look at the different zones and R-value (insulating value) requirements for residential buildings:

The International Residential Code (IRC) also sets standards for energy efficiency for single and dual-family homes up to three stories above-grade. It currently requires R30 to R38 in attics and ceilings, R-10 to R-15 in basement walls, and R-13 up to R-25 for floors and walls, depending on your zone.

Texas Commercial Building Insulation Code Requirements

For commercial buildings, the current building envelope R-value requirements per IECC 2015 by zone are below:

Products that Meet Texas Building Code Requirements

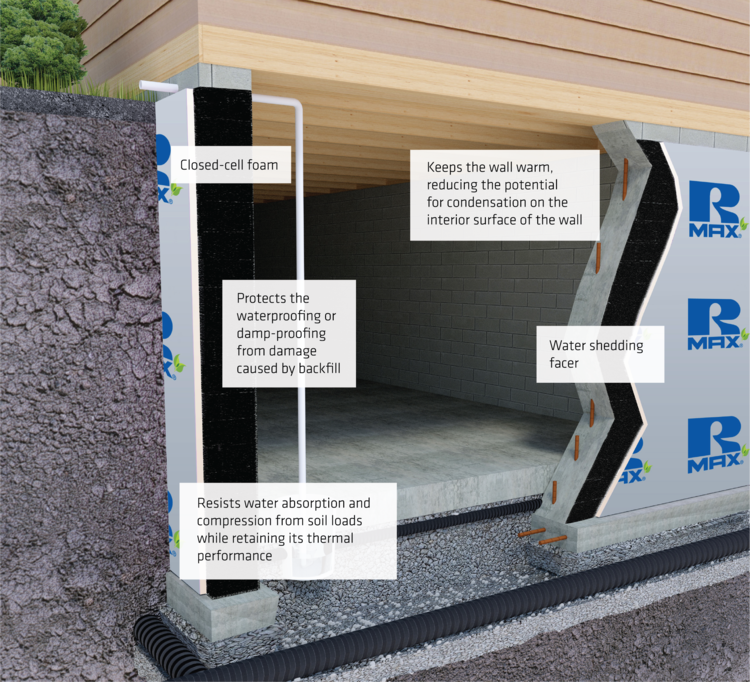

Once you’ve confirmed your insulation requirements at the local level, it’s time to look for the right insulation product for your project. Rmax stays current on building codes and carries code-compliant insulation so that contractors have one less thing to worry about when it comes to adhering to codes.

When Rmax products are installed as directed, they meet or exceed code requirements.

To help envision your design and build with the right materials, try out this wall calculator tool. Enter the details such as—code designation, zone location, and insulation values to preview your wall section and make sure it passes energy codes.

Each Rmax product has passed a series of rigorous tests. Find out which codes and tests each product has passed by visiting the product page. Here are a few Rmax polyiso insulations that are compatible with Texas building code requirements and carry an impressive R-value of 6 per inch:

Durasheath® for walls

Thermasheath® for walls and ceiling

Rmax Experts Can Help You Pick the Right Polyiso Insulation

Failing to meet building codes can slow down your project before it hits the ground running. Take the time now, during the design phase—to make sure you’ve got it right before you apply for a permit.

If you’re in the process of selecting the right building materials to meet code requirements in Texas, reach out to your designated Rmax representative today, who can help you choose the right code-compliant insulation for your design.