Building codes are used to make sure that buildings are built safely and energy efficient. A local jurisdiction’s building codes set the minimum for how well a building must be constructed. Building codes can evolve as information changes or new materials become available. Understanding the requirements for insulation keeps you adhering to the code and can save you time and money.

Building Code Standards

Building codes are adopted by local towns and cities and can vary all across the nation. These codes are typically adopted from standards published by knowledgeable organizations in the industry. Some municipalities adopt new standards into their building codes much quicker than others and are something any building owner should be aware of.

What Organizations Create Standards?

Some of the most popular organizations for creating standards are:

American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE)

North American Insulation Manufacturers Association (NAIMA)

American Society for Testing and Materials (ASTM)

International Energy Conservation Code (IECC)

As these organizations publish standards, local jurisdictions review their building codes and decide what new standards they want to adopt into their building codes.

Standards That Affect Insulation

Some standards that are often used in building codes to set requirements for insulation are ASHRAE 90.1, NAIMA 202-96, and ASTM C 665.

NAIMA 202-96, for instance, is a certification that insulation manufacturers use to ensure that their products comply with the minimum requirements of that standard. Inspectors from the National Association of Home Builders (NAHB) make quarterly unannounced visits to the factories that produce certified insulation. The inspectors review quality control procedures, records, and randomly test products to ensure the insulation meets the requirements of the certification.

Standards like ASHRAE 90.1 prescribe what types of insulation must be used when building different kinds of buildings. These standards define items like “continuous insulation” and break down the amount of insulation required for different climate zones in the U.S. These standards help ensure that everyone is speaking the same language when it comes to insulation and building standards.

What Insulation Meets Code Requirements?

Certified products help you know whether or not a certain product will meet code requirements. Insulation is not always produced in the same way for use in all different applications. For example, NAIMA 202-96 Certified Metal Building Insulations are fiberglass insulations intended for use in metal buildings, specifically. While they can sometimes be used in different applications, certifications help you know that a product will meet the requirements of a given standard.

Breaking Down ASTM C 665, Including Types and Classes

ASTM C 665 is an additional certification used for mineral fiber blankets that quickly lets you know if an insulation type will be acceptable. ASTM C 665 breaks insulation down into Type I, Type II, and Type III.

ASTM C 665 Types

Type 1

Blankets without membrane coverings. Unfaced insulation.

Type 2

Blankets with a non-reflective vapor retarder membrane covering one principal face. Classes A, B, and C are typically kraft-faced.

Type 3

Blankets with a reflective vapor retarder member covering one principal face. Class A, B, and C, foil-faced.

ASTM C 665 Classes

Additionally, there are three different classes (A, B, and C) that describe how membranes are faced on the insulation.

Class A

Membrane-faced surface with flame spread of 25 or less. For use in exposed applications meeting building code requirements.

Class B

Membrane-faced surface with flame propagation resistance critical radiant flux of 0.12 W/cm2 or greater.

Class C

Membrane-faced surface not rated for flame propagation resistance (for use in non-exposed applications only)

A building code will prescribe what is minimally acceptable, allowing you to find a material that meets or exceeds the requirement then easily. Ultimately, building codes provide a minimum for thermal effectiveness, fire resistance, and moisture resistance that all new buildings must adhere to.

Polyiso Exceeds Expectations and Achieves Strict Code Compliance

Because of polyiso’s exceptional performance, it often exceeds the requirements laid out in building codes making it an easy choice for code-compliant construction. Notable building codes polyiso achieves are ASHRAE 90.1, NAIMA 202-96, and ASTM C 665.

And while the great benefits of polyiso have been understood and employed for roof installations, Rmax polyiso is also the superior choice for walls and below-grade applications. Let’s take a look at what makes polyiso so effective:

Thermal Conductivity

The higher an insulation’s R-value, the better it is at insulating. Polyiso boasts an impressive 6.5 R per inch value that demonstrates its low thermal conductivity. Meeting the minimum R-value required by code requires a thinner wall when using polyiso over other insulation types.

Polyiso also provides exceptional strength and dimensional stability which makes it great for use as continuous insulation. More standards are beginning to require continuous insulation layers on buildings because they outperform cavity insulation techniques. When buildings are built with cavity insulation, the studs in the wall act as thermal bridges allowing heat to “leak” around the insulation and through the studs. Continuous insulation avoids these issues by applying a continuous layer of unbroken insulation on the outside of the building’s walls, just behind the exterior cladding.

Fire Resistance

Polyiso is a type of plastic known as a thermoset. Unlike other insulation types, when polyiso is exposed to fire and intense heat it chars instead of melting. Polyiso makes for a highly resilient insulation material that can help limit damage in case of a fire. As standards raise the minimum fire ratings that insulation types are allowed to have, polyiso will be in a great position to meet and exceed those requirements.

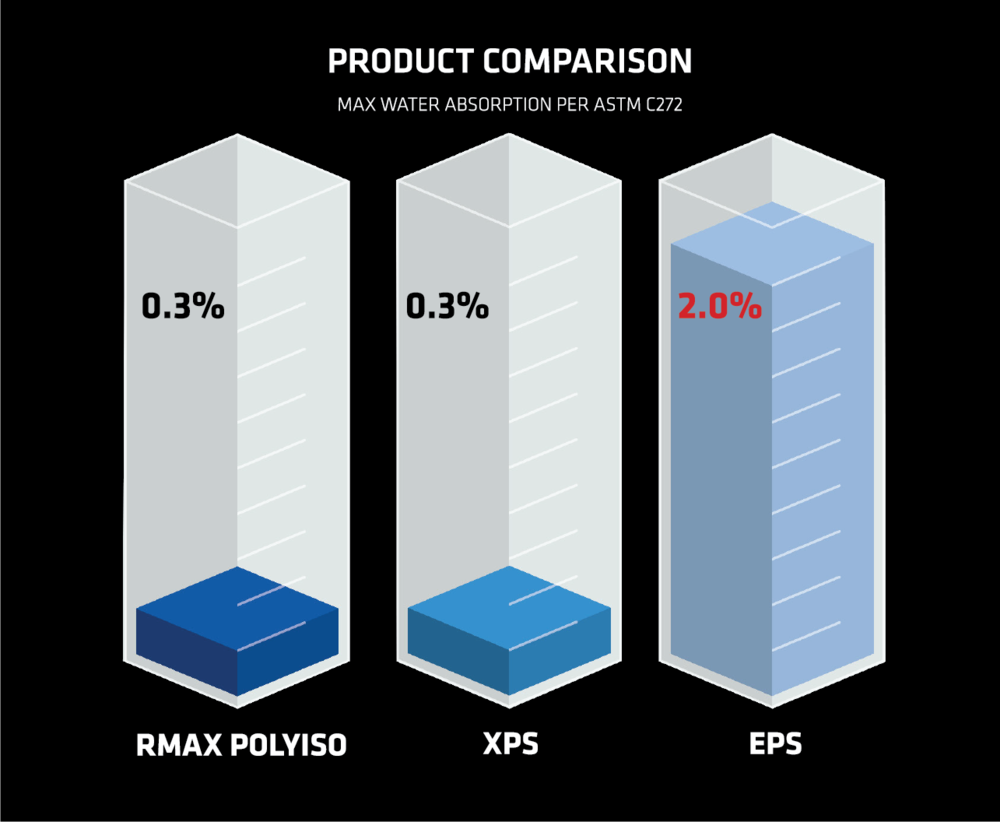

Moisture Resistance

Polyiso comes in a rigid foam board format, and it can be laminated to foil facers during manufacture. The foil face provides a built-in vapor barrier for reducing the amount of water vapor that can be transmitted through the insulation. Some insulation types are very permeable to water vapor and require additional costly vapor barriers to be added to the wall during construction to ensure the building meets code requirements.

Utilize the Best Performing Polyiso Insulation with Rmax

Rmax polyiso is high-performance insulation available throughout the USA at a competitive price. Using quality materials ensures a well-finished building and avoids headaches worrying about being code compliant. To learn more about Rmax polyiso’s extensive building code approvals, reach out to our team of insulation experts today.