Proper insulation is important to both commercial and residential buildings, but when it comes to selecting insulation, there are two options to consider: insulation boards and roll insulation.

To help you choose to identify the differences between an insulation board vs roll insulation, let’s compare and contrast these two different insulation materials.

Comparing Insulation Board vs Roll Insulation

Installation Methods

One of the biggest differences between foam insulation boards and insulation rolls is how they are installed, and each insulation type has its own pros and cons.

Installing insulation boards involves a step-by-step process that includes measuring and cutting the boards to fit the space, applying adhesive, and securing them in place. The process typically requires specific tools like a utility knife and a caulking gun. Installation time varies based on the project size, but is generally quicker than roll insulation. The foam boards are self-supporting which makes handling them much easier.

Roll insulation, on the other hand, is typically rolled out between studs or joists and may require stapling or gluing to hold it in place. Specialized tools like a utility knife and a staple gun are commonly used. The installation process can also be more labor-intensive compared to insulation boards. Roll insulation is inherently cumbersome and difficult to work with.

Insulation boards, however, offer a relatively easier and quicker installation process compared to roll insulation, which makes them a more convenient option for many projects. Insulation boards are also stronger and less likely to compress or sag during installation which allows them to retain their insulation properties better.

Application Locations

Where the different insulation types are applied can vary as well. For example:

Insulation boards are suitable for various locations such as walls, roofs, and floors. In fact, Rmax polyiso boards are known for their versatility and high performance in different applications settings, which is why they can be applied in all of these places—and more!

Roll insulation is commonly used in attics, floors, and between studs in walls. It is preferred in areas with limited space where flexibility is key.

The choice to use an insulation board vs roll insulation depends on the specific requirements of the project. Insulation boards are favored for their adaptability across different surfaces, while roll insulation excels in tight spaces.

Industry Uses

Depending on the industry, whether it be commercial or residential, the two types of insulation have a few different applications.

In the commercial sector, insulation boards are extensively used for wall and roofing applications. In residential settings, they are commonly used for energy-efficient home construction. Rmax Polyiso boards are particularly notable for their superior thermal performance and are ideal for a range of projects.

Roll insulation finds widespread use in industrial and residential projects for its ease of installation and flexibility, often being used everywhere, at times.

While both insulation types cater to various industries, insulation boards offer enhanced thermal efficiency and durability in demanding environments.

Types of Insulation

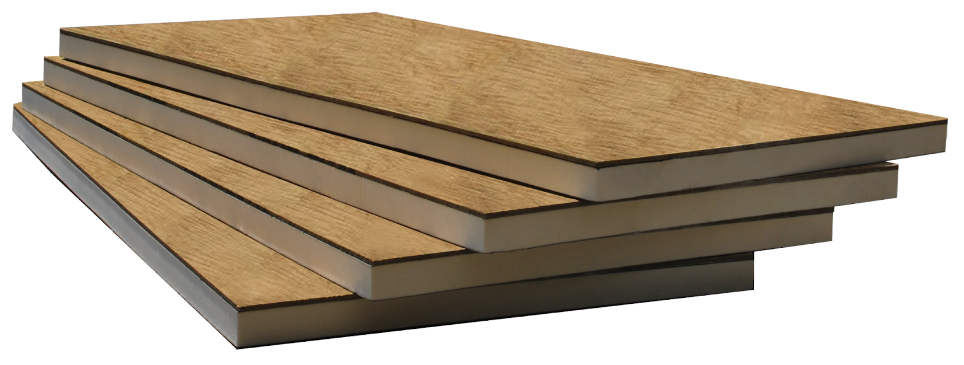

Different types of insulation boards are available in the market including XPS, EPS, and Polyiso. Among these, Rmax Polyiso stands out for its exceptional insulating properties and durability. Roll insulation comes in various forms such as fiberglass and mineral wool, each with its unique set of benefits. Insulation boards provide superior insulation properties and longevity compared to roll insulation types.

Costs

Costs for insulation boards encompass both material and installation expenses. While the initial investment can sometimes be higher, the long-term energy savings provided by Rmax Polyiso outweigh the upfront costs. With a selection of products designed for different applications, Rmax has the right solution for your project.

Roll insulation generally has lower initial costs, but may result in higher energy bills over time due to lower insulation efficiency. Roll insulation also does not retain its insulation properties as well over time which can cause operating expenses to increase along with the life of the building. Overall, insulation boards offer better value for money in terms of long-term energy savings and durability compared to roll insulation.

R-Values

Any comparison of insulation should discuss the R-values. R-values are crucial in determining a material's insulating capabilities, or how well it blocks the transfer of heat. Rmax Polyiso boasts impressive R-values, which makes it highly efficient in maintaining desired indoor temperatures with increased energy efficiency. Polyiso is so versatile it can even be used to boost the R-value in below-grade applications.

Roll insulation typically offers varying R-values depending on the material used. R-values are a function of the material’s thickness as well which is why it is imperative that roll insulation does not get crushed or compressed. Any reduction in roll insulation’s thickness will reduce the overall R-value of the material. Insulation boards, especially Rmax Polyiso, provide superior thermal insulation properties compared to most roll insulation options.

Performance

Insulation boards are known for their durability, moisture resistance, and fire resistance, which makes them a reliable choice for various applications. Roll insulation demonstrates good overall performance, but it may be more susceptible to moisture and fire hazards. Insulation boards offer more consistent performance characteristics across different environments for long-lasting insulation effectiveness.

Maintenance

Insulation boards generally require minimal maintenance due to their durable nature and resilience to wear and tear. Roll insulation may require more frequent maintenance checks to ensure optimal insulation performance. Insulation boards have a longer lifespan and lower maintenance requirements compared to roll insulation, which makes them a more convenient choice for many projects.

Replacement Costs

Factors such as damage or aging may necessitate the replacement of insulation boards. Replacement costs can vary depending on the extent of the damage and the type of insulation used. Similarly, roll insulation may require replacement due to wear and tear over time.

While both insulation types may require replacement under certain circumstances, insulation boards like Rmax Polyiso offer longevity and durability, to reduce long-term replacement costs.

For Peace of Mind, Choose Rmax Polyiso

When considering insulation options, there are many options that can make the decision difficult. Foam insulation boards, especially Rmax Polyiso, emerges as a superior choice due to their ease of installation, high performance, cost-effectiveness, and durability. Architects, engineers, and builders looking for efficient and reliable insulation solutions should consider Rmax Polyiso insulation boards for their projects.

Remember, when it comes to insulation, investing in quality materials like Rmax Polyiso can significantly impact the energy efficiency and comfort of your building in the long run. Research and explore the various products offered by Rmax to make an informed decision for your next project.

To learn more about Rmax, reach out to the Polyiso experts at Rmax today!